The current pandemic has brought together fans of 3D printing worldwide, who immediately responded to the demand for equipment, especially for healthcare professionals. However, the most commonly available 3D printing using FDM technology has its limitations, for example in terms of the possibility of disinfection. The solution could be a unique metal coating in this area, on which is working Assoc. Prof. Jan Podrouzek from the Faculty of Civil Engineering, BUT in cooperation with the St. Anne’s Hospital.

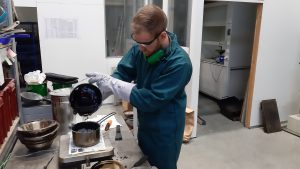

Currently, experts from the Faculty of Civil Engineering are testing the application of antimicrobial coatings on the outside of a face mask adapter made by 3D printing in the LAB machine at FME BUT and on door handles in cooperation with an industrial partner.

“Prints with the most available FDM or FFF technology are characterized by articulation and porosity, which is created by layering the material,” points out the specific properties of this type of 3D printing Jan Podrouzek. According to him, the technology is great at a time when it is necessary to respond quickly to specific requirements. It was then, he said, that coating technology could be used to improve the properties of the prints. Considered materials include, for example, oxides of copper, silver or alpaca. These technologies cost tens of millions, but the treatment of one component, for example, costs ten crowns due to the amount.

Some microorganisms can stay out of the host for a relatively long time (up to several days) and this is an important parameter when considering the rate of spread of the disease. From the point of view of spread control, therefore, apart from droplet transfer, the fundamental question of the ability of microorganisms to remain in a viable state on exposed surfaces is crucial. In the case of viruses, it is probably a matter of the interaction of material with proteins on the surface of the virus particle, but in general it is a question of controlling the surface roughness and the associated ability of microbes to survive and the effectiveness of disinfection. This is essential, for example, for the now mass-printed reductions in diving masks, which are mainly worn by paramedics, even for several hours a day. “These coatings can form a protective layer on objects that are exposed to direct, even accidental, contact with the human hand. Applying a thin protective layer cannot only reduce the risk of contamination and subsequent spread of microorganisms such as COVID-19, but also improve a number of useful properties in general, whether it is 3D printer prints or conventional injection molded plastics, “names the common use of coating Podrouzek, among others researcher of the AdMaS Center.

However, due to the possible toxicity of the materials used, it is necessary to carefully examine the possible negative effects on human health. In addition to the research of antimicrobial abilities, which will take place at the St. Anne’s Hospital, the samples will also be examined by experts in the laboratory of the Department of Physical Electronics at the Faculty of Science of Masaryk University under the leadership of Petr Vasina. There, they will focus on the durability of antimicrobial surfaces and will observe the extent to which the metal wears under mechanical and chemical stress, for example by disinfection in a hospital environment.